- #HOW DO I DELETE POINTS IN SHEETCAM SOFTWARE#

- #HOW DO I DELETE POINTS IN SHEETCAM DOWNLOAD#

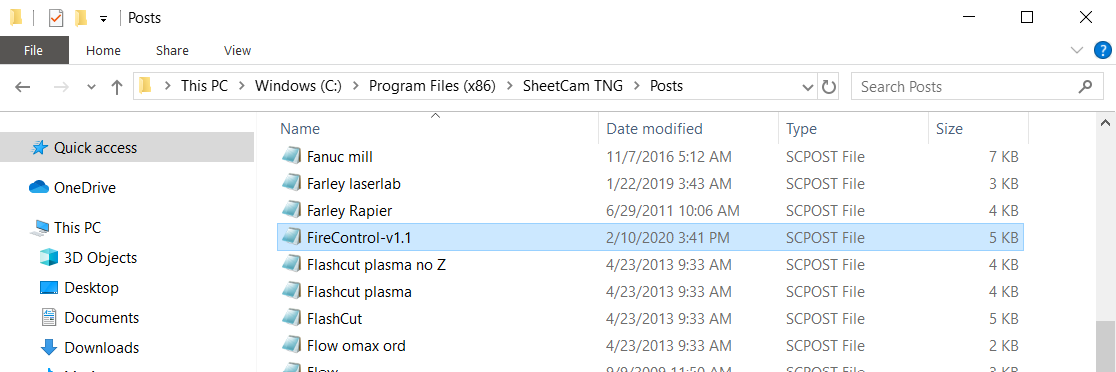

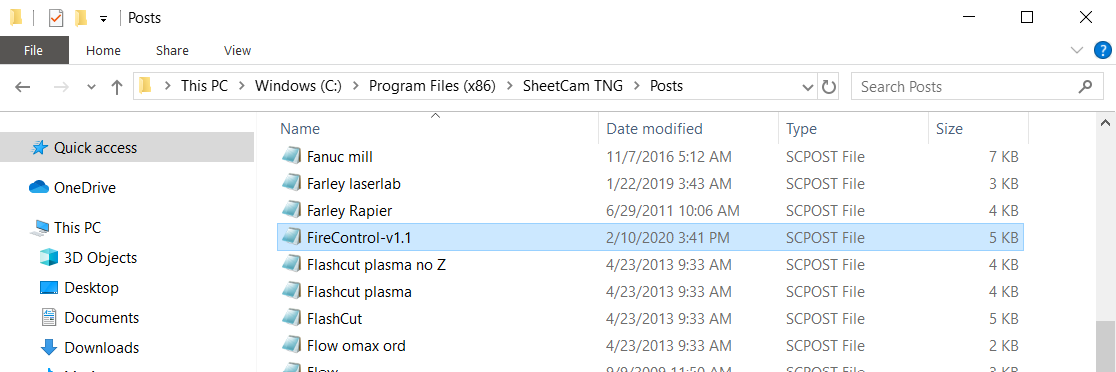

In the Post Library submenu, click Local on the left-hand side and make sure that it is highlighted. To the text field for Post in the Machine and post subheading. Go back to Fusion 360 and click the square icon with 3 dots next. Take note of the location of this file in your computer's Downloads folder or after moving this file to another permanent location.įollow the instructions provided by Autodesk for installing Personal Posts for Fusion 360. Once the file downloads to your computer,

In the Post Library submenu, click Local on the left-hand side and make sure that it is highlighted. To the text field for Post in the Machine and post subheading. Go back to Fusion 360 and click the square icon with 3 dots next. Take note of the location of this file in your computer's Downloads folder or after moving this file to another permanent location.įollow the instructions provided by Autodesk for installing Personal Posts for Fusion 360. Once the file downloads to your computer, #HOW DO I DELETE POINTS IN SHEETCAM DOWNLOAD#

You will need to open an internet browser and download the ‘Langmuir Systems Fusion 360 for FireControl Post Processor’įile from the Downloads page on our website. If this is your first time posting a program for FireControl in Fusion 360,.

To do this, click on the Post Processor icon (below) in the Additive menu bar. Telling the machine where, how, and when to move in order to cut out the part.

#HOW DO I DELETE POINTS IN SHEETCAM SOFTWARE#

A G-Code file is a set of text instructions that areįed to the CrossFire CNC electronics box through FireControl software for

Next, we are going to generate a G-Code file for this tool path using the Post. By this point, you should already have a valid toolpath created in Fusion 360įor your part similar to what is shown below. Need to be left to the Fusion360 defaults to properly set heights in your G-code program.īe sure to have these values set to the below. However, Clearance Height, Retract Height, and Top Height Actual Pierce and Cut Height Values will be set in the Post Processing step below. In the Linking menu of your CAM settings. Go back and make sure that the box for ‘ Keep Nozzle Down’ is left unchecked  If your CrossFire machine is equipped with a powered Z-axis, you will want to. Make sure you keep these tips in mind the next time you have to cut holes with a CNC plasma cutter. When you follow this tips, you end up with holes you’re proud of every time. “Overburn” simply means staying on the hole radius about. Don’t lead out into the center slug, as this warps the shape of the hole and wastes consumable life. Your hole should finish with an overburn at its end. – You avoid creating a divot in the holeWhen you use a lead-in shape that’s straight and perpendicular to the hole you cut, you set yourself up for success from the start. – Your height control has time to index down to the cut height You do this for three reasons:- It gives your plasma arc time to stabilize its pressure and energy so it cuts best Set Your Lead-In Close to the Center of the Hole. Some plasma cutters account for this automatically. However, this slower speed minimizes the hole’s taper. You will get some dross on the bottom of your hole. Whatever cut speed you use to cut the outside contour of your project, set the speed to about 60% of that when you cut your holes. Follow the 60% Rule with Your Cut Speed. When you keep the amperage lower, this allows the torch height control and motion control to react well with the plasma arc.Īnd when you set the amperage life lower, you also get a nice bonus of longer consumable life. Your manufacturer has given you charts (or they should have) that tell you what amperage to set your plasma cutter at to cut the depth you want. What Amperage Do You Set Your Plasma Cutter To?Īlways choose the lowest amperage process that allows you to pierce the metal you need to cut. Take the recommended cut height and multiply it by 1.5 – 2.0 times to get the proper pierce height to start at. Set a Pierce Height of 1.5 – 2.0 Times the Cut HeightĮasy math for you to do here. So how do you make beautiful holes without any defects on a regular basis? Here’s some tips: But you don’t always have access to machinery like that. Some companies offer automated solutions to make this process easy and consistent. The difficulty becomes greater as the hole diameter gets smaller, and especially so when it shrinks below 1 1/4”. It’s not easy to cut perfect holes with your CNC plasma cutting cutter.

If your CrossFire machine is equipped with a powered Z-axis, you will want to. Make sure you keep these tips in mind the next time you have to cut holes with a CNC plasma cutter. When you follow this tips, you end up with holes you’re proud of every time. “Overburn” simply means staying on the hole radius about. Don’t lead out into the center slug, as this warps the shape of the hole and wastes consumable life. Your hole should finish with an overburn at its end. – You avoid creating a divot in the holeWhen you use a lead-in shape that’s straight and perpendicular to the hole you cut, you set yourself up for success from the start. – Your height control has time to index down to the cut height You do this for three reasons:- It gives your plasma arc time to stabilize its pressure and energy so it cuts best Set Your Lead-In Close to the Center of the Hole. Some plasma cutters account for this automatically. However, this slower speed minimizes the hole’s taper. You will get some dross on the bottom of your hole. Whatever cut speed you use to cut the outside contour of your project, set the speed to about 60% of that when you cut your holes. Follow the 60% Rule with Your Cut Speed. When you keep the amperage lower, this allows the torch height control and motion control to react well with the plasma arc.Īnd when you set the amperage life lower, you also get a nice bonus of longer consumable life. Your manufacturer has given you charts (or they should have) that tell you what amperage to set your plasma cutter at to cut the depth you want. What Amperage Do You Set Your Plasma Cutter To?Īlways choose the lowest amperage process that allows you to pierce the metal you need to cut. Take the recommended cut height and multiply it by 1.5 – 2.0 times to get the proper pierce height to start at. Set a Pierce Height of 1.5 – 2.0 Times the Cut HeightĮasy math for you to do here. So how do you make beautiful holes without any defects on a regular basis? Here’s some tips: But you don’t always have access to machinery like that. Some companies offer automated solutions to make this process easy and consistent. The difficulty becomes greater as the hole diameter gets smaller, and especially so when it shrinks below 1 1/4”. It’s not easy to cut perfect holes with your CNC plasma cutting cutter.

0 kommentar(er)

0 kommentar(er)